Manufacturing is the foundation of a country, the foundation of a strong country, and an important part of the real economy. Our country is a country with the most complete manufacturing categories and the most complete industrial system in the world. It is also the largest manufacturing country in the world. However, in the past, our country's manufacturing industry was in a situation of being comprehensive but not refined. The equipment manufacturing industry is the backbone of a country's manufacturing industry. If China's manufacturing industry wants to truly move from the low-end to high-end manufacturing, the development of the equipment manufacturing industry plays a decisive role.

The concept of equipment manufacturing industry is unique to China and is not called that abroad. Its official appearance was seen in the 1998 Central Economic Work Conference which clearly stated that "we must vigorously develop the equipment manufacturing industry." According to the division of national economic industries, its scope specifically includes metal products industry, general equipment manufacturing industry, special equipment manufacturing industry, automobile manufacturing industry, railway, shipbuilding, aerospace and other transportation equipment manufacturing industry, electrical machinery and equipment manufacturing industry, computer, Heavy industry among eight industry categories including communications and other electronic equipment manufacturing, instrumentation manufacturing, etc.

The earliest equipment possessed by humans is humans themselves. Through the command of the brain and the coordination of eyes, ears, mouth, nose, hands and feet, various tools with different uses are produced. These tools can be roughly divided into three types: human tools, animal tools, and natural tools. The greatly improved human productivity has directly promoted the development of human civilization.

(1) Human tools

Human tools are the earliest types of tools produced by human beings themselves. The earliest humans used wooden arrows for hunting, which undoubtedly reduced the difficulty for humans to obtain food and allowed humans to initially appreciate the convenience brought by tools.

Later, it was discovered that wooden arrows polished by stones were more effective, and the Stone Age officially began. During this period, humans invented stone tools for different uses based on rocks of different properties. For example, flint and hornfels were sharpened and used as cutting tools or weapons; basalt and sandstone were used to make stone grinding tools; in the late Stone Age, clay and other materials were also used to make pottery. At the same time, wood, bone, shells, antlers and other materials were also widely developed for different uses; later, with the emergence of smelting technology, a large number of various metal tools emerged. The invention of these tools has played a role in promoting the development of human civilization.

(2) Animal-drawn tools

Although the emergence of human tools has facilitated various human production activities, manpower is limited after all. Based on the urgent need to improve productivity, Xizhong of the Xia Dynasty invented the car in the 22nd century BC, ushering in the era of animal-powered tools. Since then, humans have invented production tools such as columbians and plows based on domesticated large-scale livestock such as cattle, horses, and donkeys. It has further improved productivity, greatly increased the upper limit of the number of human groups, and enhanced the overall risk resistance of the group.

(3) Natural force tools

Neither human nor animal power can match the power of nature. Common water has become one of the natural forces that humans have mastered and widely used.

The water bucket is a machine that uses water power to pound rice and shell it. It appeared in the late Western Han Dynasty. There are records about the water bucket in the "Huanzi New Treatise" written by Huan Tan (about 23 BC - 50 AD) in the Han Dynasty. Using water buckets, grain can be processed day and night. Water dams can be set up on the banks of streams and rivers. Multiple water dams can also be set up according to the water potential. Setting up two or more water dams is called continuous dams. The most common one is to set up four water dams. "Tiangong Kaiwu" depicts a water dam. The picture of the wheel driving four worms. This device is still in use in some remote areas.

The water mill was invented around the Jin Dynasty, and there are differences depending on the impact force of the water flow in the place. Where the impulsive force of the water is relatively large, the power part of the water mill is a horizontal water wheel. The impulsive force is relatively small, but the amount of water It is relatively large, and the power part of the water mill is a vertical wheel. With the advancement of machinery manufacturing technology, people later invented a water mill with a relatively complex structure. One water wheel can drive several mills to rotate at the same time. This type of water mill is called a water-rotating continuous machine mill. "Wang Zhen Nong Shu" has records about water-driven continuous milling. The water wheel of this kind of hydraulic processing machinery is high and wide. It is a vertical wheel that needs to be driven by rapid water. The wheel axle is very thick and the length should be moderate. On the axle Three gears are installed at a certain distance apart, each gear is connected to a ground gear, and the three grinding wheels in the middle are connected to the two ground wooden teeth next to each. The water wheel rotates and drives the middle grinding wheel through the gear. When the middle grinding wheel rotates, it drives the side grinding wheel through the wooden teeth on the grinding wheel. In this way, one waterwheel can drive nine mills to work simultaneously.

In the "Wang Zhen Nong Shu" of the Yuan Dynasty, there is also a record of the water-turning keel waterwheel of irrigation equipment. This equipment has a history of nearly 700 years.

To sum up, the earliest equipment possessed by human beings is themselves, which has a strong ability to learn and grow, and creates increasingly complex tools for various purposes, which also distinguishes humans from other animals. Human beings used their own equipment to give birth to a prosperous handicraft industry in ancient times, which has promoted the reproduction and development of human civilization to this day, and also laid the foundation for the birth of China's equipment manufacturing industry.

At the end of the Qing Dynasty, my country's modern equipment manufacturing industry began to sprout, transforming from handicraft workshop-style small-scale production to a production method using power machines. In 1840, the outbreak of the Opium War forced China to accept advanced Western science, technology and equipment. At the same time, a powerful political faction - the Westernizationists - was formed in the bureaucracy. In order to resist domestic unrest and foreign aggression, China's earliest equipment manufacturing industry, the military industry, emerged under the advocacy of Westernizationists.

In 1862, my country's first machinery factory, Anqing Ordnance Institute, was founded by Zeng Guofan, a representative of the Westernization movement. China's first steam engine was made by the Anqing Ordnance Institute in April 1862. Subsequently, the Anqing Ordnance Institute made a small steamer in November 1863, and the "Huanghu" steamship in the spring of 1866. From then on, the prelude to China's modern industrial development officially kicked off. By 1911, the Westernizationists successively established 26 manufacturing bureaus (also known as machine bureaus) in Shanghai, Nanjing, Fuzhou and other places to manufacture guns, cannons, ammunition, warships and repair parts. arms.

During this period, the Westernization movement cultivated a number of technical talents and introduced a number of advanced Western production technologies, which had a profound impact on the development of the equipment manufacturing industry.

Due to the rise of the modern military industry and the financial constraints of the Qing government, by the 1870s, the Westernizationists began to actively turn to civilian enterprises such as shipping, mining and metallurgy, textiles, telecommunications, and railways, hoping to open up new financial resources. As a result, the civilian equipment manufacturing industry operated by national capitalists began to rise. In coastal areas such as Guangzhou and Shanghai, some handicraft workshops began to undertake ship repair business. With the accumulation of funds and technical experience, some workshops gradually developed into small machinery repair factories. By the beginning of the 20th century, as the domestic market demand for the repair and maintenance of machinery products gradually increased, the equipment manufacturing industry operated by private capital had developed to a certain extent, forming ship repair and construction, gin and reeling machine manufacturing, textile and knitting machine repair and maintenance, and printing presses. Manufacturing, machine installation and utility repair specialties. By 1913, there were about 7 machinery enterprises in the country with capital of more than 10,000 yuan. China's equipment manufacturing industry achieved initial development. At this time, national capitalism showed sufficient vitality and vitality, laying the foundation for the future development of the equipment manufacturing industry. . However, these enterprises run by national capital are too small in scale, not competitive, and do not have the background of bureaucratic capital. In the end, they can only survive in the cracks.

During the rule of the Beiyang Warlords, China's equipment manufacturing industry once experienced a period of prosperity and development. The development of industry during this period was closely related to the policy tendencies of the Beiyang government. The implementation of a series of industrial policies, to a certain extent, removed the obstacles for the national bourgeoisie to engage in industry, improved the investment environment for the national bourgeoisie, and greatly promoted the development of the national bourgeoisie. With the vigorous development of industry and commerce, China's national capital has entered a "golden age" in developing equipment manufacturing industry. Although civil war continued in the late period of the Beiyang Warlords' rule and foreign investment continued to be squeezed out, national capitalism at this time showed sufficient vitality and vitality, laying the foundation for the future development of the equipment manufacturing industry.

During the Anti-Japanese War, the Nationalist Government still insisted on focusing on economic development and transferred a large number of industrial and mining enterprises and technical personnel from coastal and riverine areas to the rear, providing material conditions and a relatively sufficient technical talent market for the development of equipment manufacturing industry in the rear. During this period, based on the need to support the protracted war of resistance, the Chinese government accelerated the development of equipment manufacturing industry, which significantly changed the pre-war situation of uneven distribution of industrial areas and unreasonable structure of light and heavy industries in China.

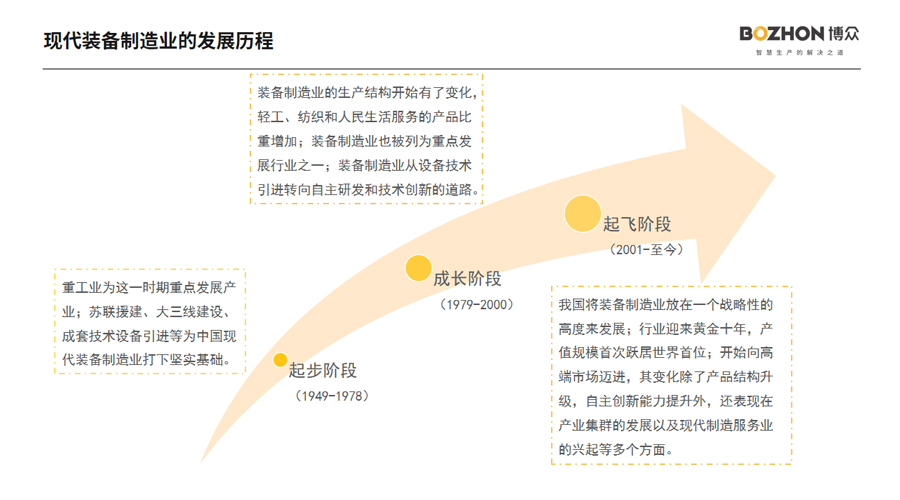

After the founding of the People's Republic of China, China truly started the process of industrialization and modernization, and the history of China's modern equipment manufacturing industry began. The development of China's equipment manufacturing industry is closely linked to China's industrial development policies. Various industrial policies have affected the development path of China's equipment manufacturing industry to varying degrees. According to the different stages of China's economic development, it can be divided into the initial stage, the growth stage and the take-off stage.

(1) Initial stage

After the founding of New China, in order to build China from a backward agricultural country into an advanced industrial country, the country chose the strategy of giving priority to the development of heavy industry in the early days of the founding of the People's Republic of China and began the construction of socialist industrialization. The equipment manufacturing industry during the "First Five-Year Plan" period mainly started with the aid of the former Soviet Union. The technology and original production equipment at that time were almost all imported from the former Soviet Union. At the same time, with the all-round help from the former Soviet Union, Chinese companies accumulated certain management, production and trade experience, and trained a large number of talents, all of which played an important role in the construction of the equipment manufacturing industry in the following decades.

In January 1961, the Ninth Plenary Session of the Eighth Central Committee of the Communist Party of China was held. The machinery industry also made large-scale "shutdown, suspension, merger, and transfer" adjustments to address its own problems, improving the supporting capabilities of enterprises. During this period, the main characteristic of the development of China's equipment manufacturing industry was the transition from general ordinary products to large-scale, precision products and general complete sets of equipment.

During the period of national economic adjustment, China successively introduced 84 items of complete sets of equipment and technologies in chemical fiber, metallurgy, petrochemical and other fields from Japan, Britain and other countries, with a total use amount of US$300 million. The introduction of these equipment has improved the technical level and production capacity of these departments.

On June 6, 1964, the country put forward the requirement to speed up the "third front construction" and strengthen combat readiness. The scope of the third-tier construction is all located in the central and western regions of China. The total investment in the equipment manufacturing industry in the "third line of construction" is 4.2 billion yuan, and a total of 124 large and medium-sized equipment manufacturing projects have been completed. Although the starting point of the third-line construction is to prepare for war, this policy has objectively changed the spatial layout of China's equipment manufacturing industry. This large-scale, well-directed investment and construction has objectively initially changed the unreasonable distribution of the country's industrial industry in the east and west, promoted the economic, technological and cultural development of inland provinces and regions, and provided basic conditions for future construction of the western region.

With the beginning of the Cultural Revolution, the newly established order in industrial management during the adjustment period was violently impacted. The relevant management agencies of the machinery industry were almost in a state of semi-paralysis, and many key enterprises in the industry were on the verge of bankruptcy. Some companies even launched fierce "power struggles" and suffered heavy losses.

Of course, in the 1970s, the wave of introduction of advanced equipment and technology led by government departments was also another force driving the development of China's equipment manufacturing industry. The introduction of complete sets of technical equipment this time will promote the accelerated development of the equipment manufacturing industry, shorten the gap with the world's advanced level, establish and develop economic and trade cooperation relations with Western developed countries, and even contribute to the subsequent opening up to the outside world and participation in economic globalization. and competition, all play a role in connecting the past and the future.

(2) Growth stage

The impact of the Cultural Revolution seriously hindered the development of productive forces. Socialist modernization required institutional reforms. As a result, China's equipment manufacturing industry has achieved all-round adjustments and transformations.

After the Cultural Revolution, due to the adjustment of the proportion of the national economy, the social demand structure has changed greatly. The development of heavy industry has slowed down, and the equipment and accessories required for the light industry market, transportation, etc. have increased significantly. The production structure of the equipment manufacturing industry has begun to change. The proportion of products in light industry, textiles, and people's daily life services has increased; maintenance accessories have been strengthened. production and supply; in the process of expanding service areas, the company's adaptability has been improved.

After the Cultural Revolution, the equipment manufacturing industry across the country began to adopt a number of policy measures in order to improve product quality and improve technical levels. In 1984, the Third Plenary Session of the Eleventh Central Committee passed the "Decision of the Central Committee of the Communist Party of China on Economic Structural Reform", and China began to move towards a market economy. Subsequently, the reform was further deepened and the separation of management rights and ownership was implemented, which mobilized the enthusiasm of operators and enterprise employees.

The most significant breakthrough in the management system reform of the equipment manufacturing industry is the gradual shift from direct management to indirect management. Industry management departments have begun to shift their attention from micro-mandatory management to focusing on strengthening macro-coordination of the entire industry. Through a series of management system reforms, new vitality has been injected into the development of the equipment manufacturing industry.

During this period, the scientific research system of the equipment manufacturing industry also underwent a series of reforms. For example, expanding the autonomy of research institutes, implementing a technology contract system, piloting paid transfer of scientific research results, and developing various scientific research and production consortiums have enhanced the vitality of scientific and technological work in the equipment manufacturing industry and created conditions for the development of new products.

Since the reform and opening up, China has successively opened up special economic zones, coastal port cities, coastal economic open zones, Bohai Rim open zones, inland cities along the river, and cities along the inland borders. After the opening of special economic zones and coastal port cities, these cities took the lead in developing equipment manufacturing industries by utilizing foreign investment and introducing technology, and have made certain progress. In Shenzhen, 24 machinery factories had started production by 1985, and some companies had begun exporting to earn foreign exchange.

Under the guidance of the opening-up policy, from the 1980s to the early 1990s, with the deepening of reform and opening up, China began to vigorously develop its own industry, and the equipment manufacturing industry was also listed as one of the key development industries. During this period, China accelerated the pace of industrial technology upgrading. The number of projects signed and transacted increased year by year, and a large number of advanced technologies and equipment were introduced. At one time, there was a "tide of equipment introduction." By the end of the 1980s, a total of about 1,200 technologies had been introduced, and the equipment manufacturing industry had become the industry with the most introduced technologies and the most extensive content, promoting the rapid development of the domestic equipment manufacturing industry.

From the 1990s to the early 2000s, the equipment manufacturing industry was mainly characterized by independent research and development and technological innovation. During this period, China increased its investment in scientific and technological research and development, actively promoted independent innovation, and promoted the independent research and development and production of some major technical equipment. For example, China's independently developed first aircraft carrier "Liaoning", large-scale water conservancy engineering equipment, large-scale coal mine fully mechanized mining equipment, etc. are all important achievements achieved during this period.

(3) Take-off stage

Entering the 21st century, China has also realized the important role of the equipment manufacturing industry and placed it at a strategic level for development. Especially during the "Eleventh Five-Year Plan" period, the country has consolidated the important position of the equipment manufacturing industry through a series of policies. In 2006, the country issued the "National Medium and Long-term Science and Technology Development Plan 2006-2020" and the "Several Opinions of the State Council on Accelerating the Revitalization of the Equipment Manufacturing Industry" and their supporting policies, which provided strong policy support for the independent innovation of the equipment manufacturing industry. . In 2009, the "Equipment Manufacturing Industry Adjustment and Revitalization Plan" was issued in response to the global financial crisis, which is conducive to the industrial upgrading of the equipment manufacturing industry and enhances industrial competitiveness. In 2010, in order to seize the commanding heights of a new round of economic and technological development, the State Council issued the "Decision on Accelerating Strategic Emerging Industries", which upgraded seven major fields to strategic emerging industries in the new era, including equipment manufacturing, new energy industry and New energy vehicles are directly related to the equipment manufacturing industry.

After receiving strong support from policies and improving macroeconomic environment, China's equipment manufacturing industry has ushered in a golden decade of rapid development, and the industry as a whole has got rid of the stagnant state of the previous 10 years. In these ten years, the output value of China's equipment manufacturing industry ranked first in the world for the first time. The total industrial output value of the entire industry increased from 1.44 trillion yuan in 2000 to 14.38 trillion yuan in 2010, with an average annual growth rate of more than 25%; The number of enterprises above designated size has increased from 33,600 to more than 100,000; the scale of assets has increased from 1.96 trillion yuan to 10.4 trillion yuan; the added value of the equipment manufacturing industry has increased significantly from 9.2% to about 19% of the national industry, accounting for The proportion of GDP increased from 3.7% to about 9%. The import and export trade achieved a surplus for the first time. The output of major machinery products such as automobiles, power generation equipment, machine tools, and large and medium-sized tractors ranked first in the world. Breakthroughs were made in many major technical equipment such as power generation equipment and power transmission and transformation equipment. The technical level of some products Already close to or reaching the world's advanced level.

In addition to the growth in scale reflected in the above figures, with the rapid development of high-tech technologies such as information technology and automation technology, China's equipment manufacturing industry has begun to move towards the high-end market. Product innovation has become a key factor in enterprise development, and efforts are being made to promote product technology. Upgrades and brand building. China's equipment manufacturing industry has begun to enter a new stage. Chinese enterprises have begun to vigorously promote informatization construction, apply various information technologies to transform traditional industries, and gradually embark on a path of independent innovation. The technical content and quality of products have been greatly improved, and gradually An internationally competitive brand has been formed. For example, the digital factories and smart manufacturing promoted by Chinese companies are all new technologies that emerged during this period.

In addition to upgrading product structure and improving independent innovation capabilities, changes in the equipment manufacturing industry are also reflected in the development of industrial clusters and the rise of modern manufacturing service industries.

In order to comprehensively improve the quality and level of development of my country's manufacturing industry, in May 2015, the State Council officially issued "Made in China 2025" as an action plan for the first ten years of comprehensively promoting the implementation of the strategy of manufacturing a strong country. "Made in China 2025" proposes to adopt "three "Step by step" to achieve the strategic goal of a manufacturing power: the first step is to enter the ranks of manufacturing powers by 2025; the second step is to reach the middle level of the world's manufacturing power camp by 2035; the third step is to reach the level of the People's Republic of China At the 100th anniversary of its founding, its status as a manufacturing power has been further consolidated, and its comprehensive strength has entered the forefront of the world's manufacturing powers.

In addition, the "14th Five-Year Plan for In-depth Integration of Informatization and Industrialization" issued by the Ministry of Industry and Information Technology sets out the goal of accelerating the digital transformation and upgrading of the equipment manufacturing industry. By 2025, the digital control rate of key processes will reach a development goal of 68%. In addition, local governments have also increased investment in the equipment manufacturing industry and promoted the development of the industry.

According to data released by the Ministry of Industry and Information Technology, the overall operating income of my country's equipment manufacturing industry is expected to reach 45 trillion yuan in 2022, a year-on-year increase of 8%. Among them, the operating income of the special equipment manufacturing industry has the fastest growth rate, reaching 11.04%. The operating income of the computer, communications and other electronic equipment manufacturing industries accounts for the highest proportion. The operating income in 2022 is expected to reach 12.1 trillion yuan.

Judging from the current development status of the industry, the equipment manufacturing industry has formed a certain scale and is constantly expanding. In terms of the industrial chain, a number of enterprises of considerable scale and level have been formed. These enterprises play an important role in product research and development, manufacturing and marketing. In addition, the market demand in the equipment manufacturing industry is also increasing, especially in the field of high-end equipment manufacturing, where the market demand is relatively strong.

However, my country's equipment manufacturing industry also faces some challenges, such as the need to further improve product technology and strengthen brand influence. Judging from the current international and domestic development status, my country's equipment manufacturing industry is in urgent need of transformation and upgrading, from "Made in China" to "Intelligent Manufacturing in China".

To sum up, the development process of the equipment manufacturing industry is closely related to the social political system and economic system. Different era backgrounds and economic systems will inevitably have different impacts on the development of the equipment manufacturing industry. Looking back at history, it is not difficult to find that timely encouragement policies will have a positive impact on the equipment manufacturing industry, while backward policies that cannot keep pace with the times will cause fluctuations in the development of the equipment manufacturing industry.

In short, the development of China's equipment manufacturing industry has gone through a transformation and upgrading process from imitation to independent innovation, from low-end to high-end, and from the domestic market to the international market. Today, my country's equipment manufacturing industry has made great achievements in development, but it also faces some challenges. In the future, my country's equipment manufacturing industry needs to strengthen technological innovation and brand building, improve product quality and brand influence to adapt to changes in market demand, and also need to strengthen industrial chain integration to improve the overall competitiveness of enterprises.