The digital factory is shining with fascinating colors, and the manufacturing industry is being attracted by its light. However, amid the glory, many companies are also confused by various contradictory and entangled concepts. Everyone is eager to have an artifact that can open up everything. The digital factory is indeed a light path with a clear trajectory. It guides those who must take the road to understand smart factories and Industry 4.0.

Digital factory: the only way forward for the development of Industry 4.0

Definition of digital factory Although there are more and more studies on digital factory at home and abroad, there is no unified conclusion on the definition of digital factory. For now, there are two definitions of digital factory, one is broad and the other is narrow.

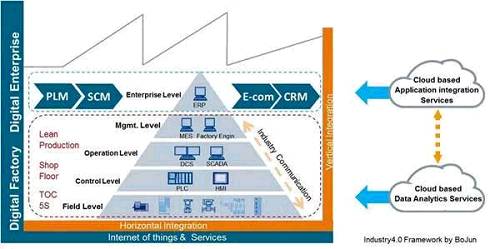

The generalized digital factory takes the manufacturing enterprise that produces products or provides services as the core enterprise, and its associated members, including core manufacturing enterprises, suppliers, software system service provider partners, collaborative manufacturers, customers, distributors, banks, etc., making it A dynamic alliance for the digitization of all information in the production and operation process. The digital factory in the narrow sense takes manufacturing resources, production operations and products as the core, is based on product life cycle data, and applies simulation technology, virtual reality technology, experimental verification technology, etc. It is the product at the production station. An integrated organization method that virtualizes all real activities in production units, production lines, and entire factories, and simulates, tests, analyzes, and optimizes processing and assembly processes. The concept that the author prefers and adopts is the digital factory in a narrow sense. In fact, this is also in line with the actual understanding of factories and enterprises. The digital factory digitizes product information, process information, and resource and material information, and effectively combines these three digital flows. It is the manufacturing process of a real factory (including design, performance analysis, process planning, processing and manufacturing, quality inspection, and production). Process management and control), a mapping on a computer. Digital factory, smart factory and Industry 4.0 - There are too many words to describe Industry 4.0. Simply put, it has two dimensions. The technical dimension is the application of the Internet of Things and services in the manufacturing industry, and the business dimension is user-driven. Its two major themes are also familiar to readers. The first is "smart factory", which focuses on the study of intelligent production systems and processes, as well as the realization of networked distributed production facilities; the second is "intelligent production", which mainly involves the production logistics management of the entire enterprise. Human-computer interaction and the application of 3D technology in industrial production processes, etc. There is a smart factory between the digital factory and Industry 4.0. Regarding the stages and implementation prerequisites of Industry 4.0, Professor Liu Qiang of Beihang University once said a very classic "three don't principles". First, do not do automation without mature technology. If the technology is not mature, it is best to do it first. Production line, this is a problem solved by Industry 2.0. Second, don't do informatization when management is immature. This is a problem that Industry 3.0 solves. Third, don't do intelligence without the foundation of networking and digitalization. This is the problem that Industry 4.0 solves.

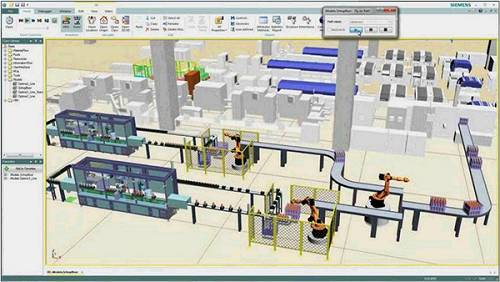

Digitalization itself is actually a part of intelligence, an entrance; and smart factories are based on digital factories and add emerging technologies such as Internet of Things technology and various intelligent systems to improve the controllability of the production process and reduce manual intervention in the production line. The digital factory is the foothold of the smart factory, and the smart factory is the foundation and foothold of Industry 4.0. Only by realizing the digital factory can it be possible to realize Industry 4.0. Path to digital factory Digital factory is based on information integration, comprehensive process integration of R&D, manufacturing, management and other aspects. Building a digital factory is an arduous and complex system project. The implementation of any complex system engineering is inseparable from system modeling, system simulation, system analysis and optimization, and the digital factory is no exception. First, we need to fully understand the digital factory and establish a model and reference architecture for the digital factory. Then we need a complete set of methodologies, tools, and processes to model, plan, analyze, and optimize each stage of the digital factory.

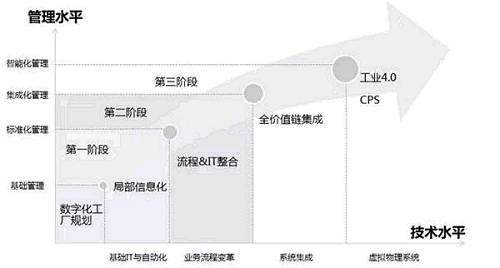

Enterprise Digital Transformation Framework The reference architecture in the picture above is the digital transformation framework model for enterprises proposed by the author after studying and referring to many Industry 4.0 framework systems. The focus is on decomposing the current enterprise situation from the management consulting dimension and IT informatization dimension. The hierarchical relationship between digital workshops, digital factories and digital enterprises in the era of intelligent manufacturing is oriented towards implementation and implementation. With the continuous selection of product development requirements for modern manufacturing, and the gradual shift of the product to multiple varieties and small batch order models, the unity and effective integration of various systems in the enterprise gradually surfaced. At present, most companies are facing the problem of transforming their original factories from basic informatization and automation to digitalization. Whether you are building a new factory or renovating an old factory, the first issue you must face is the planning of a digital factory. Each company is at a different stage. This requires sorting out the current situation of the company and tailoring a suitable digital factory plan. blueprint. As shown in the figure below, the x-axis of digital factory construction represents the technical level, and the y-axis represents the management level. The management level ranges from basic management and standardized management to integrated management and intelligent management. The technical level ranges from basic IT and automation, to business process transformation, to system integration, and finally to the realization of CPS. Enterprises can focus on the things that need to be promoted at this stage according to the stage they are in, and achieve the goals of 2.0 remediation, 3.0 popularization, and 4.0.

Digital Factory Implementation Roadmap In the process of building a digital factory, with a detailed and thorough digital planning blueprint, we have the base point and compass for the construction of the digital factory. Next, you should choose the most appropriate technology. Note here that it is not the most advanced technology. Advanced technology does not necessarily play the greatest role in the digital construction of an enterprise. Reasonable decisions need to be made based on the enterprise's own functions and usage needs. In enterprises with a relatively low degree of informatization, the use of RFID technology is not necessarily more practical than barcode technology. The construction of a digital factory in the manufacturing industry is a large system project that cannot be built and put into use in a few days or months. It requires a long implementation cycle and cannot be constructed in leaps and bounds. Each stage is based on the previous stage and is gradually advanced, and many problems are not technical problems, but changes in management, organizational methods, and concepts. This is the real test for managers. Managers need to be determined and patient. This also puts forward very comprehensive requirements for digital factory consultants: they need to understand business management, technology implementation, production operations, etc. Employee morale is also an important consideration. This is a learning and gradual process, and all three parties must be deeply immersed in it in order to promote comprehensive digital construction. Core Elements of Digital Factory Planning The core elements of digital factory construction can be summarized as digitization of factory equipment, digitization of factory logistics, digitization of design and R&D, and digitization of production processes, as shown in the figure below. Through the construction of these four aspects, innovation in product design methods and tools and innovation in enterprise management models will be driven. Related technologies of Industry 4.0 and digital factories will promote the division of labor and reorganization of the industrial chain and value chain. Traditional industry boundaries will disappear, and various new business formats and cooperation forms will be generated, forming automation, informatization, integration, leanness, Integrated digital factory.

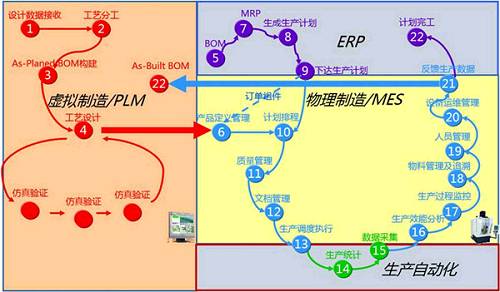

Among the core four elements, the digitalization of factory equipment is the premise and foundation for the construction of digital factories, providing basic data support for design, research and development, production and other aspects. Industrial control products, such as PLC, servo motors, sensors, etc., are still an indispensable part of the digital factory. On this basis, factory logistics can change from passive perception to active perception, achieving transparency, safety and efficiency, including product transportation process tracking, transportation vehicle tracking and positioning, material outbound, material distribution online, etc. The more important and often severed link comes from upstream design. Through the digitization of design and R&D, we can achieve a high degree of integration of design, process, manufacturing, testing and other businesses, including the integration of CAD/CAPP/CAE/CAM/PLM, virtual simulation technology, application of MDB models, product life cycle management, etc. The digitization of the production process mainly uses digital means to deal with more complex workshop production process management. The most important of these is the construction of the manufacturing execution system MES and the interaction of MES with ERP/PLM and workshop on-site automation control systems. The role of MES in the field of intelligent manufacturing is becoming more and more obvious. It is both a relatively independent software system and an enterprise information transfer router. It collects market and service, product design, MRP/ERP, supply chain and other information, and converts it into detailed production operation instructions, thereby realizing the complex product manufacturing process at the production site. Management and Control. MES upwardly undertakes the production plan issued by ERP and the product BOM verified by PLM through simulation, and downwardly connects with the on-site SCADA control system of the workshop, filling the vacuum between ERP and workshop process control, and realizing the vertical integration emphasized by Industry 4.0. and end-to-end engineering digital integration across the value chain. The picture below fully reflects the data and information flow relationship between the core systems of the digital factory, emphasizing the application boundaries and interactive interfaces between different systems.

(Reprinted from China Industrial Control Network)