From November 7th to 11th, 2017, the 19th China International Industrial Expo was held at the Shanghai International Expo Center. Bozhon presented its overall digital factory solution for 3C products, digital factory solution for the mechanical processing industry and a variety of products to explore the kingdom of smart manufacturing with the audience.

Looking back at the 2016 Industrial Expo, Bozhon showed the audience a model of a smart factory, allowing the audience to understand the basic principles of smart factory operation and Bozhon's determination to continue exploring on the road to smart manufacturing. At the 2017 Industry Fair, after a year of technological accumulation and careful thinking, Bozhon launched an overall solution for 3C product digital factory and a solution for the machining industry to further explore and practice the core of intelligent manufacturing and forge the model into a real digital factory.

This time Bozhon's booth still uses simple and elegant orange as the main color of the stage, which is eye-catching in the 7.1H hall. Of course, the stage is just a foil, the important thing is always the exhibits carefully created by Bozhon.

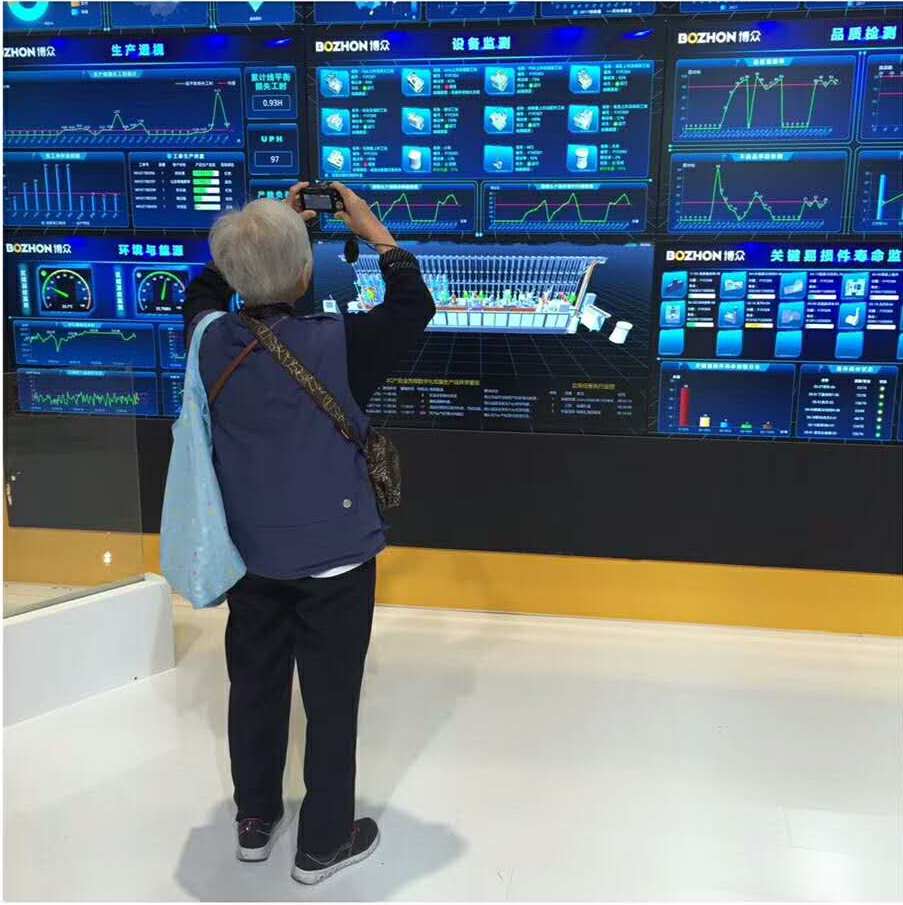

At the Bozhon 3C product digital factory, visitors can place an order on the mobile terminal and get a customized mouse in 4 minutes. Combined with lean production ideas, from order placement to product production and product delivery, order information is transmitted in real time in the automated mouse production line, automated three-dimensional warehousing, automated logistics, information management operations and other links, and is displayed on the digital management center dashboard in real time. The entire process is automated. , informatization and transparency.

At the same time as the exhibition, Bozhon held the global premiere of BOZHON digital factory, attracting CCTV2, Sina.com, Tencent.com, People.com, China.com, Phoenix.com, Sohu.com, Industrial Control Network and many other well-known media to report on it. Yang Yuqiang, chief spokesperson of Bozhon, general manager of the whole plant planning and warehouse business center, said that the era of customized services has arrived, and the digital factory uses systematic planning methods and means to integrate the three networks and interconnect them to ensure that enterprises can realize The manufacturing industry is digital, intelligent, networked and collaborative to meet the development needs for personalized, service-oriented and ecological manufacturing. At present, Bozhon has helped complete the construction of five digital factories, and its service areas cover various major industries. At this exhibition, Bozhon brought the overall solution of the digital factory for the mechanical processing industry and the digital factory for 3C products to the exhibition site, which shows its strength and determination.

In any field, mastering core technology means mastering the market. In key technical fields, Bozhon works in a low-key manner and accumulates experience. At this exhibition, Bozhon launched three types of marking equipment: TAKEIN (precision parts inspection equipment), WisdomEye (defect inspection equipment), and 3D vision intelligent grabbing system, which are suitable for different fields and different customer needs. The core technologies are all independently developed by Bozhon, and its accuracy and stability are ahead of the domestic level and comparable to foreign levels.

On November 18, the 2017 China Robot Summit Forum and the 3rd CEO Roundtable were held at the Xijiao Hotel in Shanghai. Bozhon participated in artificial intelligence and intelligent manufacturing topics and exchanged views with industry elites. Yang Yuqiang, general manager of Bozhon's whole plant planning and warehouse business center, has been working in the field of intelligent manufacturing and digital factories for several years, and has rich practical experience and a grand strategic layout. In this speech on the overall planning and implementation of smart factories, Bozhon relied on many years of experience in the automation field and the rapid development of information services and warehousing logistics services in recent years to help enterprises clarify their core advantages and development in the process of digital transformation and upgrading. Bottlenecks and find feasible landing paths based on existing conditions.

(Image source: Oriental.com)

This grandma is 80 years old, Originally from a design institute, Come to the Industry Fair every year, She said you are developing too fast now, It's all big data, it's clear at a glance, She said it's great that you are young ~ @Cynthia

In the kingdom of intelligent manufacturing, Bozhon always insists on exploration and construction to build a strong fortress. In line with the development trends of Made in China 2025 and Industry 4.0, from core components and robot research and development to overall digital factory solutions, Bozhon has taken solid steps and moved forward steadily, assisting the implementation of Made in China 2025 and providing a powerful engine for the development of intelligent manufacturing! !

Bozhon booth exciting continues

Surprises never stop

11.7-11.11

Come to the National Exhibition and Convention Center

7.1H-B253

7.1H-B253

7.1H-B253

Experience smart manufacturing and feel the future! ! !